Scroll saw blades for thick wood allow you to achieve precise cuts when working with maple, oak, cherry, walnut, and any other kinds of wood. Choosing the best scroll saw blades for thick wood guarantees that the sharpness of the blade lasts for a long time. Ensure that you compare the prices and quality of blades before purchasing so that you settle on a package that is worth your money. Ensure you purchase blades that are compatible with the scroll saw you have so you don’t have to purchase another saw to use the blades.

But now question is that, which is the best blade for thick wood cutting by scroll saw? On our extensive market research, Scroll Saw Blades for Thick Wood, 12-Pack is the winner!! It comes with low price, for cutting hard/soft wood and multilayers from 3/4″ to 2″ thick, 7 teeth per inch, width 0.08″, thickness 0.018″

What Are The Best Scroll Saw Blades For Thick Wood?

Here’s a list of the best scroll saw blade for thick wood we found on the market:

1. Best Scroll Saw Blades For Thick Wood: Scroll Saw Blades for Thick Wood, 12-Pack

2. Best Scroll Saw Blade For Cutting Letters: Flying Dutchman New Spiral Five Dozen Scroll Saw Blade Variety Pack

3. Best Scroll Saw Blades For Hardwood: OLSON SAW PG49802 Precision Ground Scroll Saw Blade

4. Best Scroll Saw Blades For Tight Turns: SKIL 80182 Plain End Scroll Saw Blade Set, 36 Piece

1. Best Scroll Saw Blades for Thick Wood: Scroll Saw Blades for Thick Wood, 12-Pack

[amazon box=”B001G9POE6″ template=”horizontal”]

Scroll saw blades for thick wood are essential tools for anyone with a workshop or a DIY fan who does woodwork projects now and then. A sharp and durable scroll saw blade would last you a long time and ensure you get precise and accurate cuts on thick wood. Ensure you compare prices of different saw blades so you settle on a reasonably priced blade that will perform as intended.

Features:

Scroll saw blades cut through hard and softwood with ease and precision. These blades are made from metal the package dimension is 5.7×2.3×0.5 inches. You can get a pin or a non-pin blade depending on the saw you have. If you purchase a pinned blade, you can remove the pin and make the blade pin-less usable.

These blades work great, and they enable you to achieve nice smooth cuts. The blades can be used to cut;

- Tiger maple

- Oak

- Cherry

- Walnut

You can easily install a new scroll saw blade on an old saw as long as the blade is compatible with the saw. Choosing the best scroll saw blade that cuts through hardwood with accuracy and speed saves you time, and you get your desired output.

Pros:

- Gives You Value for Your Money

If you run a woodwork workshop, scroll saw blades are essential tools as they are sharp and enable you to cut through thick, hard, and softwood swiftly. Their sharpness and durability make them a valuable purchase.

- Reasonably Priced

Scroll saw blades for cutting thick wood are affordable, and you can purchase even with a tight budget. Choosing blades durable with the saw you have saves you from buying a new saw. These blades perform as intended and their sharpness does not wear off.

- Compatible with Different Saws

Most scrolls saw blades are compatible with more than one scroll saw. You can use different blades with the same saw.

Cons:

- Wider with Less TPI

Scroll saw blades for cutting thick wood are usually wider with less TPI. As a result, the turning radius when using these blades is usually much less as well. Less TPI means you get rough cuts that require smoothening.

Related Post: Choosing the Best Table Saw Blade for Ripping Maple

2. Best Scroll Saw Blade For Cutting Letters: Flying Dutchman New Spiral Five Dozen Scroll Saw Blade Variety Pack

[amazon box=”B074BL1LWN” template=”horizontal”]

3. Best Scroll Saw Blades For Hardwood: OLSON SAW PG49802 Precision Ground Scroll Saw Blade

[amazon box=”B001FTKXOS” template=”horizontal”]

4. Best Scroll Saw Blades For Tight Turns: SKIL 80182 Plain End Scroll Saw Blade Set, 36 Piece

[amazon box=”B00AEBX246″ template=”horizontal”]

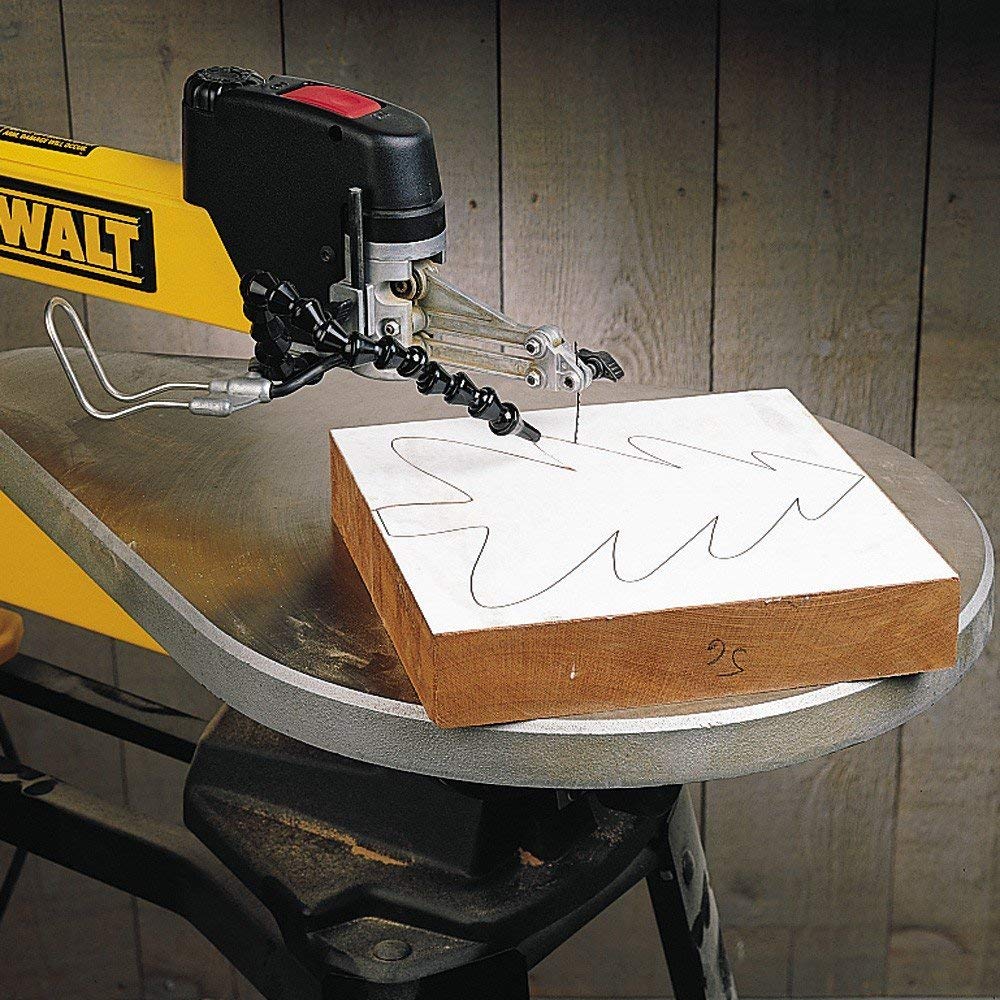

How to Change Scroll Saw Blades

Scroll saws are versatile cutting tools that require blades to function. Whether you have a workshop or a DIY fan who does woodwork projects now and then, you’ll need to change blades based on what you want to cut. Blades are designed for different purposes and using the right blade for a specific purpose ensures you get your desired output.

First off, you need to be well conversant with the instructions manual. Even if you have experience with blades and scroll saws, you should handle the blades with care as they are sharp tools that can easily cut you. Before changing the blades, ensure you examine the new blade to ensure it is the one suited for the task you are about to carry out.

Precaution procedures and the instruction manual will enable a novice to change blades without getting injured in the process successfully. Identify where the holes for screws go in the new blade before sliding into the designated blade slot. Also, remember to confirm that the blade is facing the right side before fastening it.

Once you slid a compatible blade into your scroll saw and fastened it, you should test out the saw to ensure the blade is correctly installed. Correct installation ensures you get clean and precise cuts with your blade. Also, before fastening the blade into place, you need to straighten it fast so that you get accurate cuts. You’ll need an Allen wrench or a screwdriver to unfasten and fasten the blades.

The Process of Changing Scroll Saw Blades

- Unplug Saw

First off, you should unplug the blade to prevent an electric shock. Blades are made from metals that conduct electricity and touching them while the saw is still plugged to a power source is dangerous. Once the saw is plugged, find out where the screws that fasten the blade in place are located. You can do this by referring to the instruction manual.

- Unfasten Screws

If you are working with a table saw, the screws holding down the blade are located on the top and bottom of the blade. You are recommended to use the right screwdriver or Allen wrench to unfasten the scares. If you are a novice, consider getting an extra set of hands to avoid any accidents.

- Removing the Old Blade

Depending on the saw you are working on, the blade will either slop off once the screws are loosened, or you’ll need to remove them yourself. Be careful when unfastening the screws so that if the blade slips off, it doesn’t cut you.

If you have a table saw, you’ll need to pull the blade up and towards you to remove it from the saw. For a handheld saw, the motion is sideways, and away from the saw and then downwards, to remove the blade.

- Installing a New Blade

Once the old blade is removed, you’ll need to examine the new blade before you install it. Find out where the holes where the screws go are located before slipping the blade into its slot on the saw. There is a variety of blades you can choose to install, depending on the project you want to work on.

- The positioning of New Blade

Whether you are installing a thin, thick or heavy-duty blade, ensure you place it in its slot with the teethed edge facing the right side. Ideally, the teeth should face down, unless you are installing a double teethed blade, in which case, both edges are teethed. Refer to the instruction manual to ensure you get it right.

- Fastening New Blade

Assuming that you’ve already located the holes where the screws go, use the appropriate screwdriver or Allen wrench to drive down the screws. You are required to straighten the blade before you fasten it so that you get accurate cuts from your saw. Once you are sure that you have succeeded in straightening the blade, fasten it to ensure it is properly secured in place.

- Testing New Saw

You are advised to test out you saw every time you change a blade to ensure that the installation was successful. The blade should be fastened in place and correctly installed to ensure you get the desired results when cutting materials.

The Process of Cutting Thick Wood (Step by step)

To get high-quality output when cutting thick wood, you are required to use the right blade and correctly prepare the wood. Using the Best scroll saw blades for thick wood ensures that you achieve clean and precise cuts. A woodwork project will only turn out as it should if the wood used were properly cut. Even, precise and accurate are achieved when you are keen and efficient.

Below are sequential steps to follow when cutting thick wood.

- Choosing Wood

You can either choose rough wood or surface cut wood for your woodwork project. The rough surface requires smoothening while surface cut woods are ready to use. When working with rough surface wood, you’ll need to remove the small cracks on the surface of the wood for aesthetics and also because they could extend and cause the wood to break.

- Use Jointer to Flatten Best Surface of the Wood

Use a jointer to flatten one surface on the wood and mark it, so you don’t get confused as you proceed with the project.

- Use Planer to Smoothen Best Edge of the Wood

With your planner, smoothen one edge of the wood and mark it to avoid confusion as you proceed with the project.

- Cutting

Mark exact dimensions on the wood and use your scroll saw to make precise and accurate cuts. You are to cut the reference edge against the fence of the saw.

- Eliminate Saw Marks and Make Final Cuts

Run a jointer on the surface of the wood to eliminate saw marks and make your final cuts. Work with an adjustable saw so you can achieve accurate angle cuts.

Conclusion

The best scroll saw blades for thick wood allow you to make accurate and smooth cuts. Consider purchasing blades that are compatible with the saw you have. Ensure you handle your blades with care as they could easily cut you.

Recent Post:

FAQ’s

FAQ-1: What’s the length of these blades?

Answer: The blades are 5-inches in length

FAQ-2: How many blades come with the package?

Answer: The dozen sells the blades

FAQ-3: Can the blades cut through book covers?

Answer: Yes, the blades were able to cut through book covers

FAQ-4: Are the blades pinned or unpinned?

Answer: These blades are non-pinned

FAQ-5: Can the blades cut through metal brass?

Answer: No, you need a finer tooth blade to cut through metal brass.