Do you want to calibrate a torque wrench? Are you aware of the proper procedure for calibrating a torque wrench?A torque wrench is a handy tool. It allows you to measure the twist and tension of nuts and bolts. It ensures that your nuts and bolts are tight enough without over-tightening. The tool comes with a long-armed wrench that bends with the turning force of the handle. The instrument has an internal mechanical indicator that registers the intensity of torque. The indicator is integrated with a calibrated scale. The indicator will let you know if you have reached the desired torque.

Therefore, to achieve accurate results, precise calibration of a torque wrench is important.

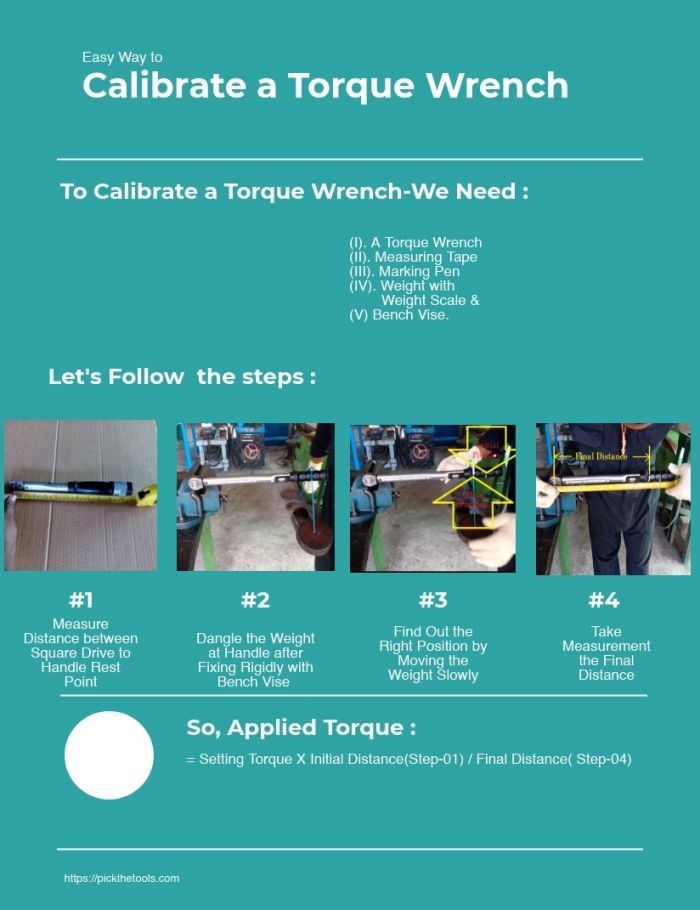

# At a Glance: How to Calibrate a Torque Wrench.

It is important that you calibrate a torque wrench properly. The proper calibration of a torque wrench ensures that you have the exact tension for the tool to function properly.

Follow the few steps for calibrating a torque wrench:

-

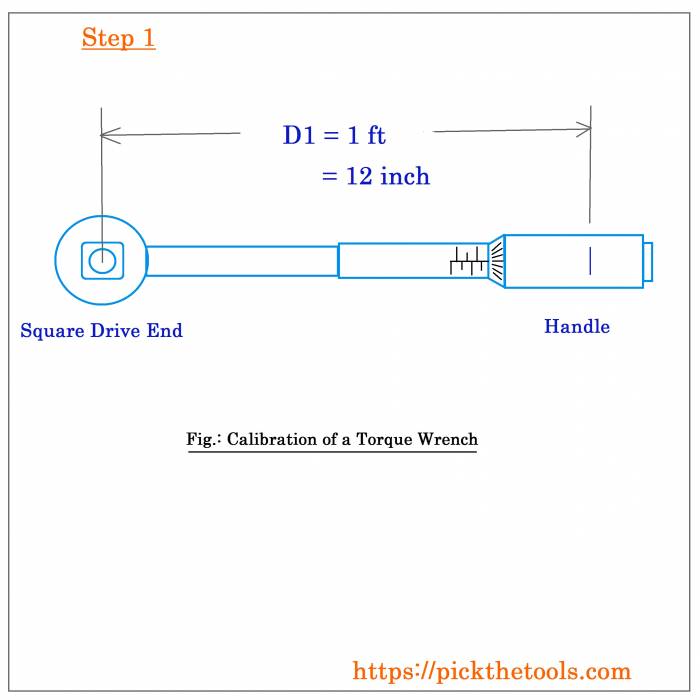

Step 1

First, you have to complete a measurement of the square drive center and the torque wrench handle where your hand rests while holding the tool. For that, identify the center point of the square head drive and make a mark in the middle of the wrenches handle. Note the measurement. For example, you have got the measurement 1 ft or 12 inches. Which is denoted on the picture by D1.

-

Step 2

Now you have to secure the wrench by placing the square drive in the vise rigidly. Avoid locking any other part of the wrench in the vise. Be aware that any kind touching of the torque wrench with a vise body will be made an error on calculation.

-

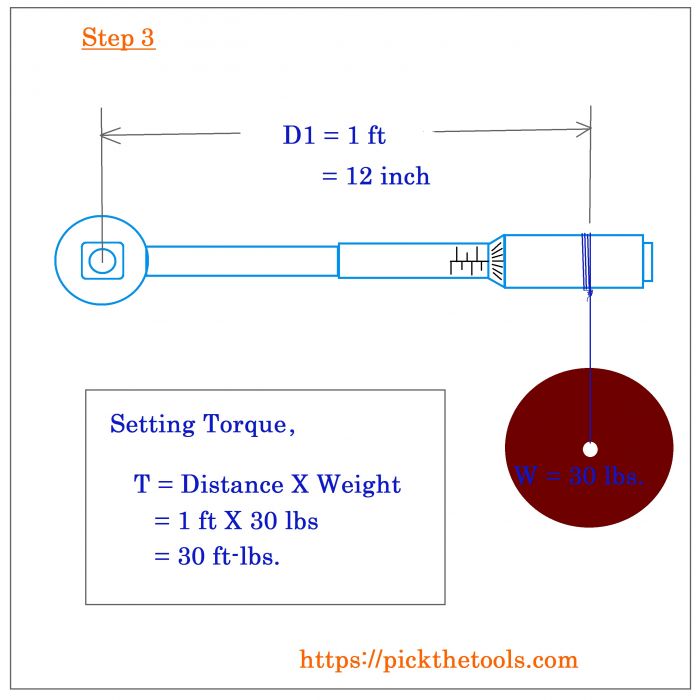

Step 3

Once you secured the wrench in the vise, you will have a value of settings. Align the torque value to the setting of the distance you got in step1 (D1= 1 ft) by multiplying 30-lbs. The calculated setting value will be 30 ft-lbs. So, 30 ft-lbs torque to be set on your torque wrench.

-

Step 4

Hang the 30-lbs (13.6 kg) weight with a thin rope on the wrench handle where your hand rests. Do you hear any clicking sound or not?

-

Step 5

In this step, you may perform two steps. Which actually depends on the error or health condition of your torque wrench.

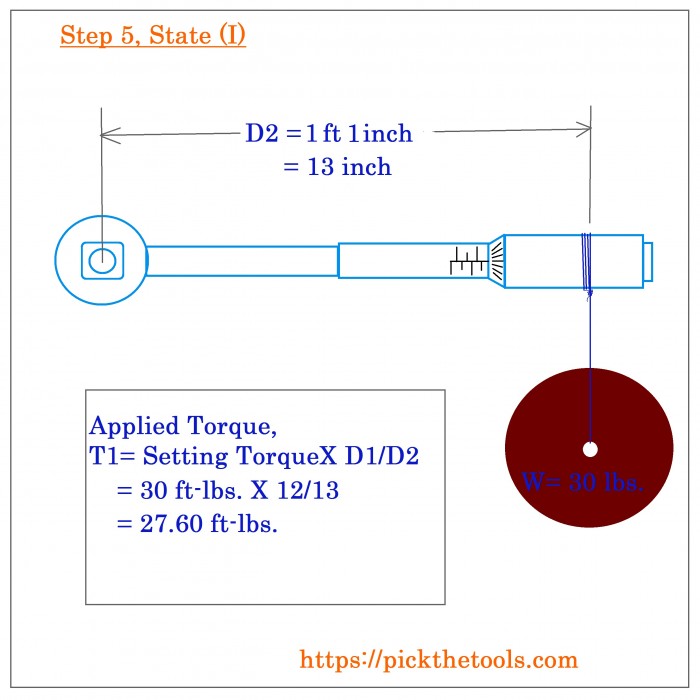

State (I) :

If your wrench gives lower torque from the setting value of the wrench then you have to carry over this state.

Evidently, you maintain a horizontal position for the continuation of this step to get an accurate value. If you hear a click from the wrench, then it’s time to lift the weight and move it gradually toward the end of the wrench. Move it until the clicking stops. Repeat the job, tune the weight hanging exact position to get the accurate value. Let’s, noted the distance is D2.

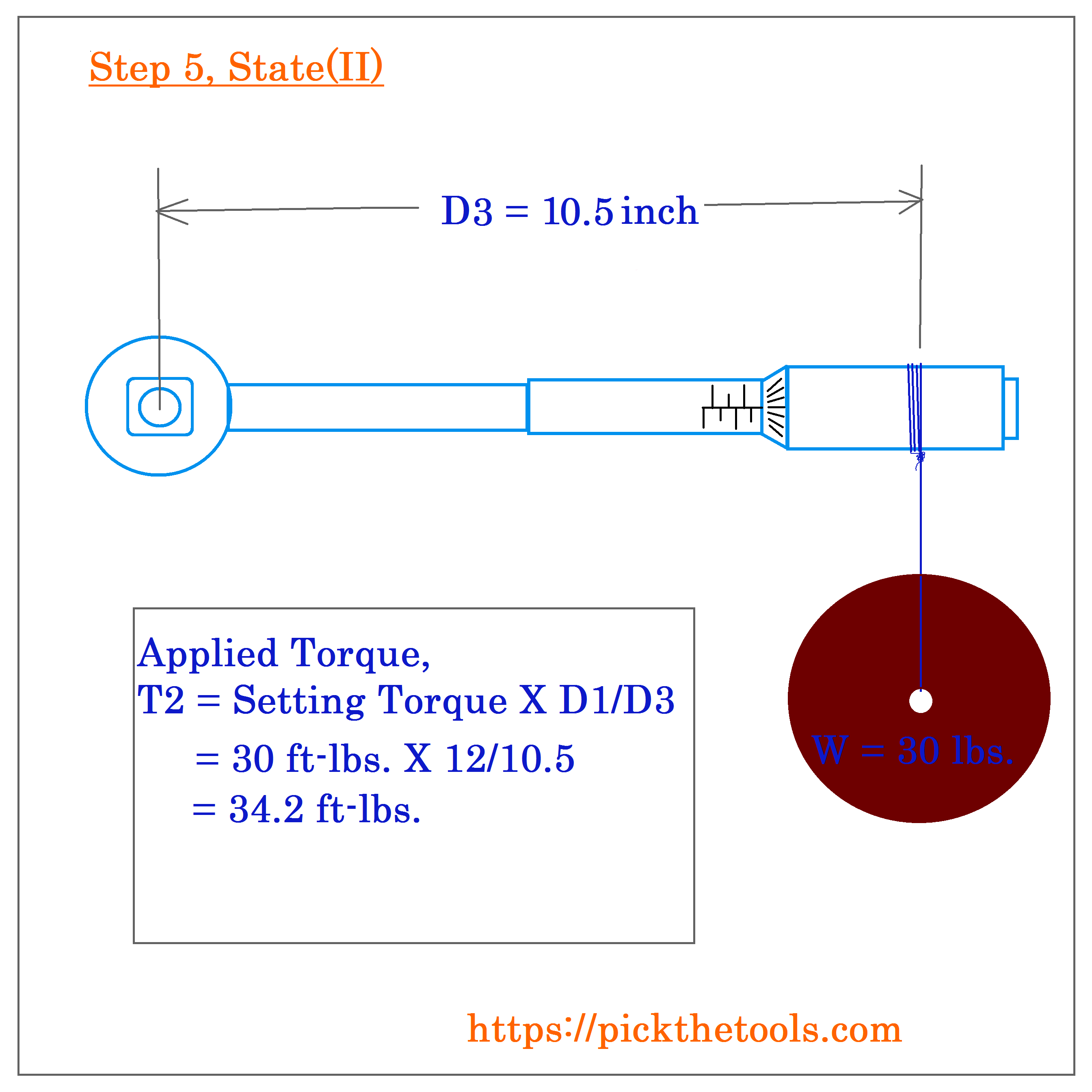

State (II) :  if your wrench gives higher torque from the setting value of the wrench then you have to carry over this state.

if your wrench gives higher torque from the setting value of the wrench then you have to carry over this state.

If you heard a click sound from the wrench, then lift the hanging weight & move it toward the square head until the click sound stop. After getting the click sound stop condition, the weight slowly moves towards the handle end. Such as a trial and error method you will get a definite position. Let’s, noted the distance is D3.

-

Step 6

Use the formula described below to calculate the applied torque with the resultant data: The formula Applied Torque= Torque setting x (Distance Determined in Step 1/Distance Determined in Step 5) According to the situation of Step 5, State#I. The calculation will be as follows:

- Applied Torque = Torque Setting (Step 3) X (Distance in Step 1, D1 / Distance Determined in Step 5-State#I, D2)

= 30 X (12 / 13) ft-lbs. = 27.60 ft-lbs. This result indicates that though you have 30 ft-lbs set on your torque wrench, your actual tightening toque will be 27.60 ft-lb. According to the situation of Step 5, State#II. The calculation will be as follows:

- Applied Torque = Torque Setting (Step 3) X (Distance in Step 1, D1 / Distance Determined in Step 5-State#I, D3)

= 30 X (12 / 10.5) ft-lbs. = 34.2 ft-lbs. This result indicates that, though you have 30 ft-lbs on your torque wrench setting, you will actually get 34.2 ft-lbs from your wrench.

Conclusion:

Calibrating the torque wrench is an important thing for getting accurate torque after a certain period. Basically, calibrate a torque wrench depends on how many times use the wrench. In this article, I discussed step-by-step to calibrate a torque wrench perfectly in the simplest way. Make sure you follow this guide for the proper calibration of your torque wrench.