The first time people knew about torque was in 1931. This was when John Sharp patented a wrench that can tell you how tight something is. It’s called an indicating torque wrench today. In 1935, Conrad Bahr and George Pfefferle invented an adjustable ratcheting torque wrench with feedback to let you know when it’s tight enough. They did this because they were frustrated with bolts being loose sometimes at their jobs, so they made this thing to tighten them up more easily.

So, how does a torque wrench work? A torque wrench is a tool that you can use to tighten nuts and bolts. So when you want things to be tight, you can use the tool. This way, it will help with not making things too tight or too loose.

Moreover, the torque wrench has a socket and an indicator to show you when the right amount of tightness is reached, so it’s pretty simple.

After you put the socket on, you turn it until the indicator is at your desired torque. Then you take it off and use that bolt or nut!

Let’s dig deeper about the torque wrench to learn even more about it!

What Is A Torque Wrench?

A torque wrench is a tool that is used to tighten screws, bolts, and lag screws. It makes sure that the fastener has the right amount of tightness. You would use a torque wrench where you need very specific tightness or where it matters a lot if bolts are too loose. For example, you would use a torque wrench to tighten the bolts on your car’s wheels.

Torque wrenches are used in many industries – for example, they are relied upon by companies that build airplanes and race cars. Torque wrenches come in manual or cordless versions.

They also come in all shapes and sizes depending on what you want to use them for – some can be calibrated to apply just a little torque, whereas others can apply very high amounts of torque.

Most models have a ratchet mechanism that allows you to turn fasteners easily without having a socket driver.

Before buying a torque wrench, you must read reviews from other users to get one that is durable easy to use.

[amazon bestseller=”Torque Wrench” items=”2″]

How does a torque wrench work inside?

A torque wrench is a type of adjustable spanner that users use to remove stubborn nuts and bolts. The heavy-duty tool works by twisting to a fastener until the desired tightening force is reached. The tool will either make a clicking sound or provide some other sort of tactile feedback to tell you when it has been tightened as much as possible without breaking the bolt–ideally just enough so that when someone tries to loosen the nut, it won’t move.

However, torque wrench work inside is varied depending on the type of torque wrench being used. There are 10 types of torque wrenches that are available in the market. The following sections go into further detail about these types of torque wrench.

- Beam Torque wrench

- Deflecting beam torque wrench

- Slipper torque wrench

- Click torque wrench

- “No-hub” wrench

- Electronic torque wrenches

- Programmable electronic torque/angle wrenches

- Mechatronic torque wrenches

- Hydraulic torque wrenches

- Pneumatic torque wrench

01. Beam Type Torque wrench

Between the late 1920s and early 1930s, a type of wrench was developed for Chrysler. This wrench is a beam-type torque wrench.

Paul Sturtevant was a Chrysler employee who wanted to make a hand tool that would measure how hard the nuts and bolts were.

He made this tool, and then he wrote letters about it to people who might want one. They sold them for $10 each. So, if you had a car, you would want one of these tools so that your nuts and bolts are tight enough.

Moreover, this type of wrench can tell you when you are done. You can see it or feel it, or both.

The most basic type of wrench is one that has two beams. One beam is used to apply the torque, and the other is the handle. When force is applied to this handle, it will bend and move, just like you would expect it to do if we went with Hooke’s law.

On the other hand, the second beam is only connected on one side to the wrench head. The other side is free. This beam is called an indicator beam. When you have a tool with two beams, the two beams are in a line when it is in a resting position with the indicator beam in front of everything else.

Although, the indicator beam is on the end of this wrench. It’s not touching anything. When you use this wrench, it makes it easier to apply force. The free end of the indicator beam will move over a scale attached to the handle or lever and tell you how much force you are using.

Thus, the end of the indicating beam points to how hard you are tightening something. This type of wrench is simple and accurate. It’s also cheap!

02. Deflecting beam torque wrench

The dual-signal deflecting beam torque wrench is a special type that uses a different principle than traditional wrenches. It has two beams, but only one will have the bolt in it.

The other beam will move depending on how you are turning it. This type of wrench uses the distance between the two beams to tell how tight something is.

Attached to the deflecting beam is a scale with a wedge on it. The wedge can be moved along the length of the deflecting beam and changed so that you can apply more or less torque to an object through its pin, which sticks out like a trigger when pressed by an adjustable button when you want to know if your car has enough power to start–and there will be a loud sound. It will shoot out, indicating that your car has enough power to start.

This wrench also works for vehicles besides cars. Some vehicles use more than one beam so that they can be measured in different ways. These vehicles do not have wrenches like this kind of torque wrench. They need a special type of wrench made specifically for them.

People who work on cars and trucks usually use more than one torque wrench to get the proper tension on their bolts. The dual-signal deflecting beam torque wrench is just one of many types of wrenches that you can use on your car or truck. There are others like it, and they each have their purpose and job to do.

03. Slipper torque wrench

A slipper-type torque wrench has two parts. A cam is attached to another part, and then the roller pushes against the cam and locks it in place. If somebody tries to make it tighter than it should be, then the wrench will slip. The wrench doesn’t force something more than enough pressure on a bolt that someone wants tightly closed.

Moreover, this tool is shaped like a cam. If you try to snap it, it won’t break. It has a roller and some springs on the inside to ensure the bolt doesn’t get too tight. If you try to use too much force and there’s not enough left, it will slip and stop tightening the bolt more than this limit.

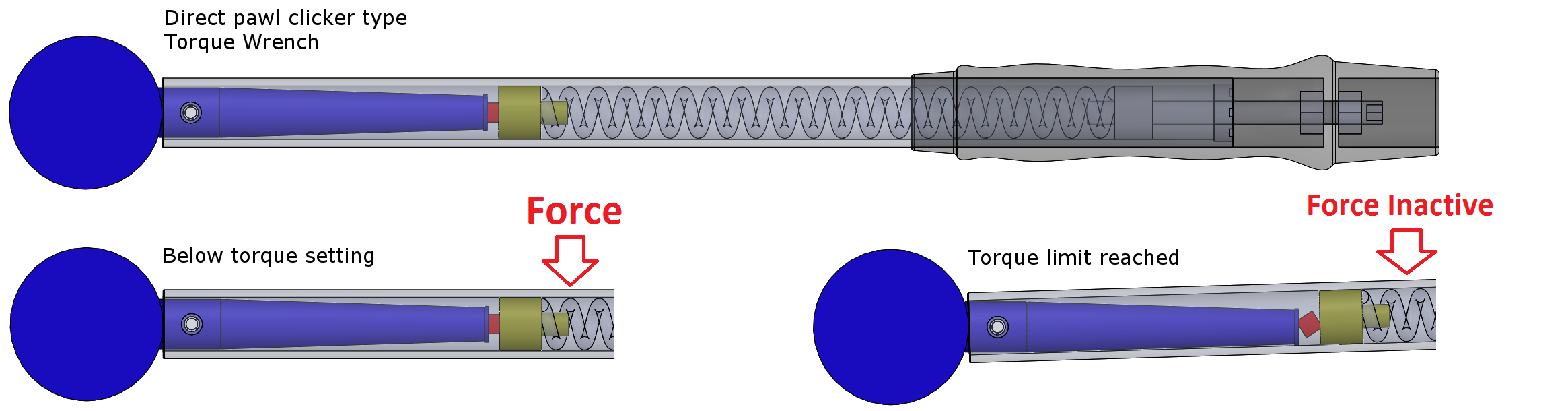

04. Click Type Torque Wrench

There are different ways that you can get the right amount of force. One way is with a calibrated clutch mechanism with a little ball inside and an adjustable screw. The screw makes the ball pop out and pushes against something so it can give you the right amount of force for what you want to do.

A ball detent is a device that transmits force until the preset torque is reached, at which point it “clicks” out of its socket. The ball detent transmits motion from one thing to another by rotating so that the force exerted by an external object such as a spring, gear, or gear train is translated into rotational motion.

Although, this design is better because it gives you feedback from the wrench. You can tell when the desired torque is reached. It won’t start slipping, but it will make a clicking sound and bend at the head. You will know when it has reached the right amount without needing to do anything else or get any warnings from your wrench.

Moreover, this design can be used in different ways. It can be used for drills that are not strong enough to tighten screws all the way. You need to ensure it’s not too tight because the drill will start slipping once it gets close to the right amount of torque.

05. “No-hub” wrench

These are special wrenches that plumbers use to tighten the clamping bands on hubless soil pipe couplings. They usually have a T-handle and a 1-way ratchet and clutch. The wrench is preset to a fixed torque which means it does not damage the coupling while securing it sufficiently.

06. Electronic torque wrenches

With an electronic torque wrench, you can measure a lot of different things. First, you have to attach a special kind of thing to the torsion rod.

It needs electricity from somewhere else. This special kind of thing is usually made out of plastic or metal, and it changes how much electricity goes through it when the wrench changes direction.

This makes an electrical signal sent to a computer inside the wrench that converts this electrical signal into something we can read like “N·m” or “lbf·ft”.

You do not need to know what those letters mean right now, but they are numbers, and they show how much force (or pressure) there is on the bolt (or nut).

The programmed limits are shown with lights or on display during tightening.

This generation of torque wrenches can remember all the measurements you make, and it is a way to know if your bolt is tight.

This wrench can read the torque and how hard you push. You can transfer it to a computer or print it on paper. The best accuracy is ±0.5% to 4%.

07. Programmable electronic torque / angle wrenches

In 1995, Saltus-Werk Max Forst GmbH applied for an international patent for the first electronic torque wrench with angle measurement. The wrench doesn’t need a reference arm because it can tell you what the right pressure is.

Torque is the measure of how tight the bolt is. Sometimes people use a wrench to tighten bolts, but they can also use an electronic torque wrench. With both kinds, you tighten it until it gets very tight, and then measure how much force you used by counting how many inches it moved up or down. For example, if the bolt has gone 1 inch down, you have used 1 pound of force to tighten it so far.

The angle measurement process can measure a joint that has already been tightened. It saves the measurements, and you can see how they compare to other joints. The machine remembers what it reads and how it is connected to the force. You can use the software on your computer to see how tight a curve is by looking at a graph of force versus position.

This type of torque wrench can also be used to tell how tight the bolts are on your car. It’s good to know how much pressure you’re putting on them. If it is too much, then it will break. There are different types of torque wrenches, but this one can help you find out if there are enough or not. Thanks to a special measuring process, it’s also possible to see the point where the bolt starts getting tighter (called yield controlled tightening) so that you know when they are at their strongest.

This wrench can tighten things, but it also lets you know if you need to turn the wrench at an angle. This is for when someone wants to make sure that they tighten something and want to make sure that they do not break anything.

08. Mechatronic torque wrenches

Torque is a type of measurement. You can measure it with a tool called a click-type torque wrench, but you can also measure it differently with an electronic torque wrench. This is a combination of the two types of tools which ultimately adds up to more accurate measurements that are transmitted wirelessly. When you have reached the desired amount of torque, the wrench will “beep” and show the setting on its digital display.

09. Hydraulic torque wrenches

Hydraulic torque wrenches are used for tightening very strong tightness. They are used for heavy machinery and aeroplanes. The way they work is that the hydraulic cylinder presses the ratchet, and then it moves freely around the teeth of the ratchet.

This goes on until you reach your desired tightness. Smaller hydraulic torque wrenches have a reaction arm built into them, which touches another part of what you’re working on to keep it from rotating while you tighten it with the wrench.

If you want to tighten something on a larger machine like an aeroplane, you can either fix it with something or hold it in place while tightening with the wrench by moving your hands around what you’re trying to turn on until there’s no more resistance.

The ratchet can be turned in both directions, so you turn it clockwise to tighten and counterclockwise to loosen the bolt/nut/screw you’re working with.

The smaller models will give you an accurate reading of how tight something is by releasing pressure on it while turning the ratchet counterclockwise until there’s no longer any tightness left.

When tightening bolts or nuts, you want to start them by hand before using the wrench because if you tighten bolts too much, they might snap under pressure, which could hurt somebody or damage what you’re tightening them on even more than they already are.

If somebody over-tightens a bolt, it will warp either the surface where it’s tightened onto or the bolt itself.

10. Pneumatic torque wrench

Pneumatic torque wrenches were first made in Germany. They can be used on bolts of a lot of different sizes. Some bolts need 118Nm, and others use 47,600Nm.

Moreover, the most common power for a pneumatic torque wrench is compressed air. It needs to have 20-25 CFM.

A pneumatic torque wrench is a tool for tightening bolts with air pressure. At the end of the wrench, a thing converts air pressure to torque, which can be used with little effort by the person using it. The amount of torque depends on how much air pressure you use.

Although, planetary torque multiplier gearboxes have a multiplication ratio up to 125:1. They are used in situations where accurate torque is required on a nut or bolt or in a situation when you need to remove a stubborn nut. These gears are often used for critical applications, and the final torque is often applied with a high-accuracy tool.

Moreover, a pneumatic torque wrench is used to tighten bolts. It is different from a standard impact wrench because it has gears that make it not vibrate.

Conclusion

If you’re looking to learn how a torque wrench works, we hope this blog post has helped clear up some confusion. A torque wrench is designed for either tightening or loosening nuts and bolts with precision – perfect for those hard-to-reach places and tight spaces! As the saying goes, knowledge is power; learning about what tools like these can do will make your next DIY project that much easier.

We hope you now have a better understanding of how torque wrenches work and can make an informed decision about which one to purchase.

Related Post: